Milltech: specialists in the milling and manufacturing of mechanical components

Milltech produces high-quality mechanical components and is highly specialized in milling.

It was founded by a team of technicians with many years of experience in the world of mechanics and its main company asset concerns competence and experience. It supports the customer from the design to the prototype, up to the creation of the finished piece, meeting any request or need.

It produces mechanical components for manufacturers of medical, optical, electromechanical, optometratronic, packaging and aerospace sector. Depending on the request, it works with other companies supporting them in the different processing phases.

Always looking for the extremely high working and production standards, Milltech is a company that continuously invests in acquiring resources and competences in order to improve the most important and delicate stages of the process: from the design to the prototype.

All the advantages

of our supply chain

The experience in the Milltech sector allows us to offer customers adequate operating solutions, which involve a decrease in costs.

The company boasts a network of partners specialize in particular processing, guaranteeing very high quality standards and a full supply from every point of view. Saving time and money, in fact, the least number of entities involved ensures a reduction of waste, gaining the best quality at the best price.

MACHINING

Experience and high precision for the highest-level milling

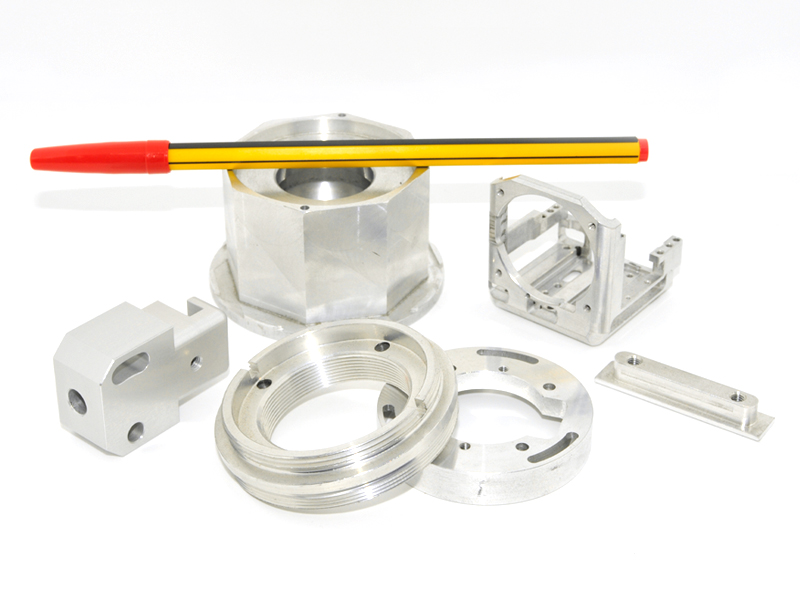

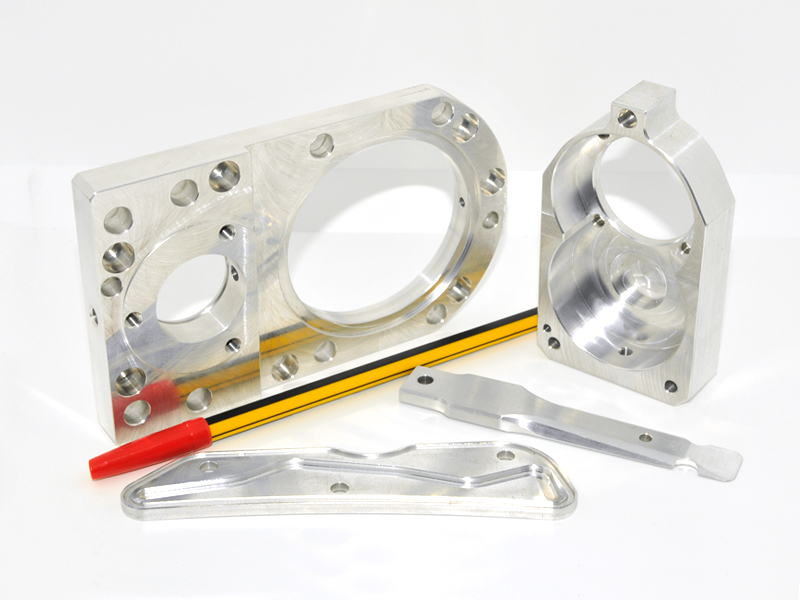

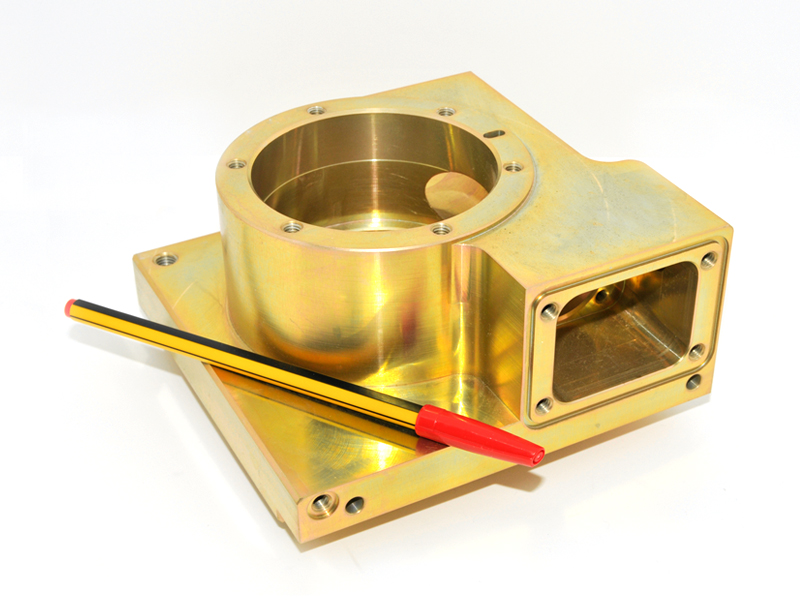

With its extremely specialized milling department, Milltech offers a high precision and complexity service. Thanks to its experience, it meets any customer’s need with a customized and personalized approach, by satisfying the manufacturers of mechanical components and of many other realities that need a high and extremely specific milling and turning service.

The company offers:

- Drillings of minimum 0.5 mm. Concentricity.

- Minimum milling radius of 0.5 mm

- Milling of high complex mechanical and micro-mechanical components. It processes three-dimensional surfaces which are difficult to execute

- Machining of castings

- Bar and full milling

- Base plates drills

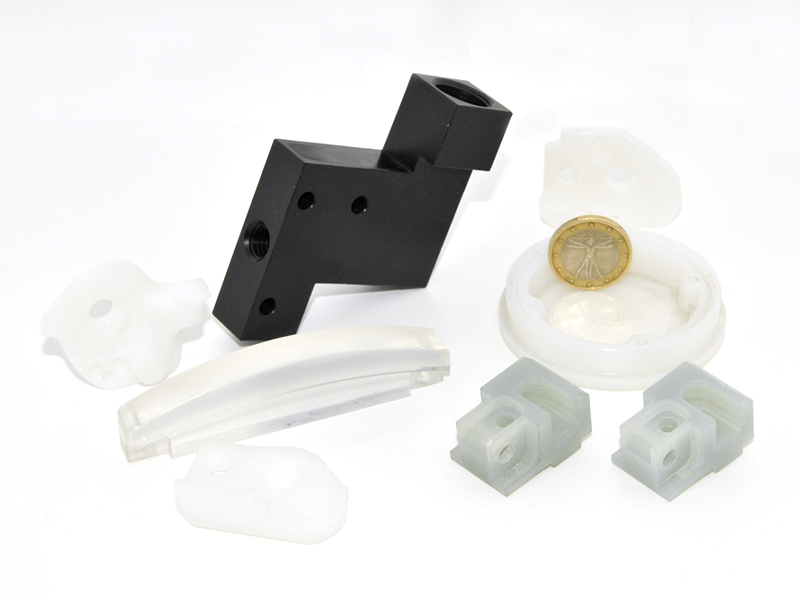

- Milling of all types of plastic materials

Furthermore, for the extruded profiles, Milltech supports the customer during all the stages, from the design of the product, up to the purchase of the extruded elements, passing through mechanical processing and the potential surface treatments in order to deliver ready to use components.

MACHINING

Production of mechanical components: support in all stages of processing

Milltech has always performed the entire production cycle of the required mechanical parts, providing a finished product with high quality standards and supporting the customer during all processing phases:

- Consultation. Treatments, finishes, materials, mechanical processing, tolerances and other fundamental aspects are designed in the initial phase

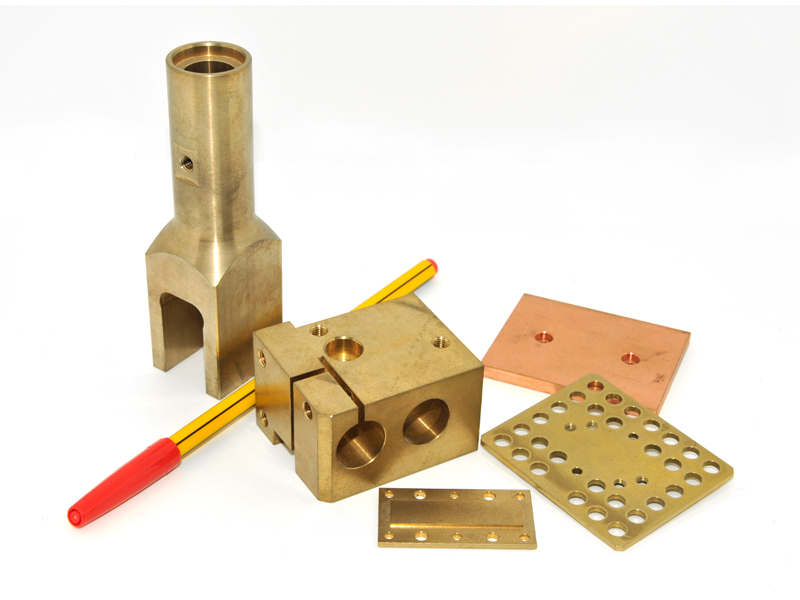

- Turning – from bars, castings and extruded elements – of complex mechanical and micro-mechanical parts, precision micro-mechanics, flanges, precision small parts, pieces of important lengths

- High-precision milling and drilling from the full of plates and mergers

- Special processing (painting, thermal, chemical and other treatments)

- Test

- Packaging

The company, on behalf of the customer, is able to deal with the management of the different suppliers to obtain the finished pieces, guaranteeing a saving of time and money.

Milltech processes various materials, aluminium and all its alloys, steel, stainless steel, titanium, brass and plastic material generally, extruded materials and mergers. Furthermore, it offers the customer the advantage of flexibility, thanks to the agility of its production structure: it can quickly pass from small to medium series with lots ranging from 5 to 10,000 pieces.

MACHINING

Prototyping and mechanical production in the field of research

Milltech collaborates in finalization, prototyping and production of mechanical parts for the sectors in which the research is a key phase of the process and the prototype is the protagonist: the astrophysical, aerospace and medical sectors.

Here too, the company makes the difference. It works in a context in which the project becomes reality and the operational suggestions make the piece actually achievable. Features that are synonymous with excellence and skills higher than the average, allowing them to operate in extremely demanding and cutting-edge sectors.

Here too, the company makes the difference. It works in a context in which the project becomes reality and the operational suggestions make the piece actually achievable.

Contact us now

You will find a team at your complete disposal

for any business need.